At HTF, we continue our manufacturer spotlight series. With great pleasure, we now turn to our partner, RAF, to highlight the electronic standoffs they produce. It’s time to select the proper standoff for your application, but how should you go about that?

The First Step – Spacer Type

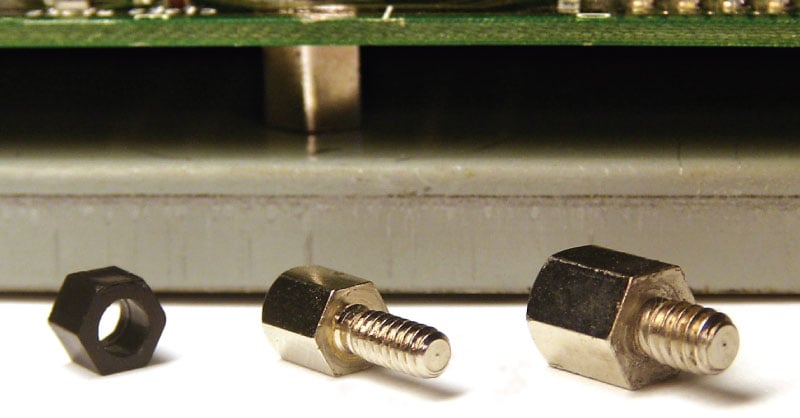

The best way to consider standoffs are as three sections: two threaded ends and the main part of the body. There are several categories of standoffs based on the threaded ends. These consist of the female-female standoffs, male-female standoffs, and male-male standoffs. Let’s break these three styles down even more:

Female-Female Standoffs

Another name for female-female standoffs is threaded spacers. These come with female threads on both sides of the part. It allows a screw or male standoff to be installed on either end. The longer of these parts will be threaded to a minimum thread depth. The shorter options could be threaded the entire length of the part.

Male-Female Standoffs

As you may have already guessed, male-female standoffs consist of one end with a male thread and the other end with a female thread. A great application of this part is for stacking circuit boards. The circuit boards can be stacked with each male thread being installed into the mating part’s female thread. The benefit of this is to reduce the number of fasteners needed in the overall assembly while also cutting down on installation time.

Male-Male Standoffs

Male-male standoffs have male threads on each end and are used for connecting two female threaded components. Another common use for this part is as thread adapters for converting a female thread to a male thread. The male-male standoffs can be the same on each end or a different thread for a wider range of uses.

The Second Step – Thread Size

Standoffs are available in every standard thread size and have both inch and metric options. It is most common to find them in the same thread size on both ends, but they are made with unique thread sizes on either side. To get different thread sizes, customers would need to make a special request.

The Third Step – Body Length

As discussed earlier, standoffs are often used to separate multiple components. With the exposed portion between these components being the body, standoffs come in a wide range of length options. The consistent, secure fit of the standoff is essential, and this is why the parts are machined to very tight tolerances. Standoffs are available by request in custom lengths and tolerance.

The Fourth Step – Outer Diameter

The outer diameter (OD) of the standoffs comes in a variety of standard diameters to choose from. This allows for the exact fit and function for any application. The larger OD makes for a thicker standoff, which adds strength and rigidity. Because of the added wall thickness, it will hold up to demanding applications without warping or bending during installation. It will also add surface to protect from damage to soft and delicate materials. On the other end, smaller OD’s create a thin standoff, which is perfect when the space or weight is the primary concern with the application. The smaller the OD, the smaller the footprint of the standoff, giving room for other parts and providing a reduction in weight.

The Fifth Step – Profile

Fifth in the line of considerations is the profile of the standoff. They come in hex, round, and square profiles. Hex spacers are chosen when being installed with wrenches or pliers and round or square spacers are nice for a clean look. When installed in assembly lines, many customers choose to select different profiles for each step on similar parts to provide a visual difference on the line.

The Sixth Step – Material and Plating Options

The sixth and final step when selecting a standoff is choosing the material it is made of as well as a plating option. When choosing a spacer, the most common considerations are corrosion, rust resistance, magnetism, electrical conductivity and strength to weight properties. Other considerations include color and cost.

HTF is here to help

HTF carries the full line of RAF electronic standoffs, and they can be procured with reduced lead times on standard sizes and materials and custom options upon request. Not only will you find a diverse range of industry-standard parts, but you can get them with same-day shipping. HTF offers many support services for their valued customers, including stocking on a daily basis at discounted volume rates. Reach out today; we are here to help.