A drawer slide is the mechanism which guides a drawer while it is operated. There are many different types of drawer slides to best support applications of all sorts, but they all accomplish the same goal.

Very simply put, the goal is to support the proper operation of a drawer by holding it in place and smoothly guiding it open and closed when being pushed or pulled by the operator. Drawer slides are found in a multitude of household and industrial applications.

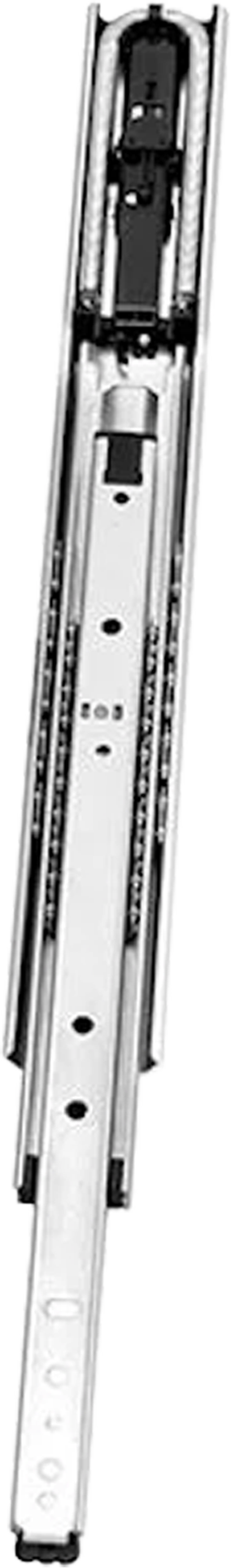

A simple drawer slide consists of an inner member called a drawer that attaches to the side of a drawer box, and an outer (or cabinet) which attaches to the cabinet’s inner wall surface within the drawer opening. In this system only one of the slide members moves when opening the drawer. In a two member slide the drawer, or outer member, is the moving element.

Alternatively, the more complex slide system consists of three members with an intermediate member added to the setup. This is found between the cabinet and drawer members. In this system only the drawer and intermediate members move. The cabinet member is fixed to the cabinet structure and does not move while the drawer box is being operated.

There are several different styles of drawer slides designed to best support the drawer style and function of the cabinet in which they are integrated.

As previously touched on, slides come in two arrangements, side-mounted and under-mounted, with most drawer slides being side-mounted. An undermount slide mounts in a position allowing a specially designed drawer to sit on top of the suspension. The undermount is used when the drawer slide component needs to be hidden from view when in operation.

There are two larger categories that most drawer slides fit into—roller slides and ball bearing slides. The first on our list are the ball bearing slides which include drawer slides that operate by utilizing ball bearings as a latching mechanism to achieve the telescopic movement. There are three different components to these slides which are the cabinet member, the intermediate member and the drawer member. There are two sets of ball bearings on these slides and they both interact with the intermediate member while being operated. The ball bearings allow the drawer to be pulled out horizontally while remaining stable.

Soft Close, much like the traditional ball bearing drawer slides explained above, operate in the same way, but as the name describes close softly. The resistance at the end of the closing motion prevents slamming of the drawer box. Both styles of ball bearing drawer slides are used in residential and industrial cabinetry and furniture. They both provide greater strength and durability over the lifetime of the application.

Top mount drawer slides are mounted to the top fixture and the sides of the drawer. This slide is most often used for applications like pencil drawers and computer keyboard trays. These slides allow for access to the back of the drawer while remaining stable.

So far in our review of drawer slides they have all been two slide systems, however the center mount drawer slides are a single slide. The center mounted slide is no longer the first choice for most applications. It can limit drawer height and holds less overall weight than most drawer slides can manage and remain stable.

The under mount drawer slide is used when the slide mechanism should be unseen to emphasize the design or craftsmanship of the drawer. They attach to the sides of the cabinet and the bottom of the drawer. The under mounting of the slide is beneficial when horizontal space is limited.

Likely the most popular, or at least well known, the side mount drawer slides attach to the sides of the cabinet and the sides of the drawer. The side mount slides come in both roller and ball bearing designs and do well with most applications. They are only limited by the amount of horizontal space needed for the drawer.

A roller slide system has two main parts, the furniture rail (attached to the cabinet), and the drawer rail which of course is secured to the drawer. Both of the rails have roller wheels instead of ball bearings which are designed to fit into the other rail. Roller slides do not typically hold up as well as ball bearing slides, however they will be the more affordable option.

Most of us don’t appreciate how important drawer slides are in our everyday life both at home and out in the world. Drawer slides are used in home furnishings and cabinetry as well as in industrial and commercial applications.

Choosing the right drawer slide for the application is an important step in the overall design of a product. There are many features to consider when choosing hardware for drawers and pull outs like strength, length, depth, and mounting style.

Additional important features to consider include the drawer motion, slide extension type, and disconnect type. Let’s review these in more detail below.

Drawer motion defines the way a drawer opens and closes utilizing specific drawer slides designed to meet the desired motion type. The first style is self-closing drawer slides and, like their name, suggests these slides are designed to make closing the drawer as easy as possible. They require only a slight pressure or push on the drawer to initiate the self-closing feature. Next are the push-to-open drawer slides. Push-to-open drawer slides require pressure on the drawer face when the drawer is in the closed position. This pressure causes the drawer to begin the opening motion. The push-to-open drawer slides are ideal for sleek cabinet designs where a hardware free look is desired. Finally, soft-closing drawer slides feature resistance at the end of the closing motion to prevent drawer slam and to ensure the drawer closes fully on its own.

The drawer slide extension determines how far the drawer will open based on the extension range of the slide. The majority of drawer slides in the home setting do not open to their full extension, making accessing the back of the drawer difficult. Full extension drawer slides allow the drawer to open fully wil the back of the drawer box flush with the cabinet face. Over-travel extension allows the drawer to open beyond the face of the cabinet. Slides allowing for over-travel extension work well when the cabinet has an overhang at the top, like an extended countertop, so that the back of the drawer can still be seen and accessed. As mentioned before, the traditional extension type in most applications is the ¾ extension. This is the most limiting option for access and visibility.

The disconnect type determines if and how the drawer can be disconnected from the cabinet. The disconnect function is accomplished by mechanisms in the drawer slides allowing for the release of the drawer box. HTF partner, Accuride International, has a variety of slides with different disconnect methods. Below the types of disconnect options are explained in more detail:

There are many options for drawer slide lengths on the market today, and there is sure to be one for every application both residential and commercial or industrial. Most drawer slides found in home furnishing and cabinetry range from 10”-48”, however there are many options outside of this scale. For specialized needs Accuride has drawer slides available from 6” to 60”.

The most common type of drawer slide mount is the side mounted option. However as listed above there are many additional choices specially designed to accommodate most applications. These include center mount, under mount, side mount and top mount options.

It is important to determine the use of the drawer or pull out first when trying to decide on a drawer slide. Determining the application will tell you what kind of weight you will be applying to the drawer slides and thus the best model to support that load. Accuride’s line of drawer slides come in light, medium, and heavy duty options. The light duty drawer slides can hold up to 75 lbs and are ideal for everyday use in kitchen cabinets and home furnishings. The medium duty drawer slide holds up to 150lbs. Office furniture and large kitchen cabinets are great applications for the medium duty drawer slides. Finally, the heavy duty drawer slides hold weights all the way up to 1,300 lbs. These are seen in pull out trays like those used in first responder vehicles and utility trucks.

Load ratings are standard weight markers for components across an industry. The most common load ratings as mentioned above fall into 75, 100, and 150 lbs. However, there are many drawer slides like the Accuride 9300 series that can handle much greater loads.

Drawer slides come in different colors and finishes coated over carbon steel slide pieces. The Accuride line has zinc, black electroplate, or white electro- coat. Additional options include stainless steel and aluminum for more specific applications. Zinc is the most common option and also happens to be the most environmentally friendly. The zinc coating only offers a moderate resistance to corrosion, so if the application faces greater risk of corrosion it is better to choose a stainless steel or aluminum finish rather than zinc.

Finding a trusted drawer slide manufacturer is easy with the experts at HTF. Not only will your drawer slides arrive quickly, you can also trust that with industry leading brands like Accuride, Southco, and Device Technologies that you will be receiving the best slides for your application.

HTF has the most extensive supply of drawer slide hardware and they are delivered to you on time with excellent customer service. That’s why the top manufacturers in the industry partner with us. HTF is here to serve — reach out today to request a quote.